Understand ERP in Manufacturing

Manufacturing is a fast-moving and highly competitive industry where efficiency and accuracy decide success. From keeping production on schedule to making sure deliveries arrive on time, many manufacturers struggle with scattered processes and disconnected data. This is where Enterprise Resource Planning, or ERP, comes in. ERP brings everything together in one platform and gives manufacturers real-time visibility and control across the entire process, from the shop floor to the final product delivery.

How ERP Enhances Efficiency Across the Manufacturing Cycle

ERP helps manufacturers run more smoothly by connecting every part of the process from the shop floor to delivery. It improves production management, reduces downtime, and keeps inventory balanced to prevent waste or shortages. By bringing together suppliers, logistics, and quality control, ERP ensures products meet standards and reach customers on time. With real-time data and smarter insights, manufacturers can make better decisions, lower costs, and build stronger trust with their customers.

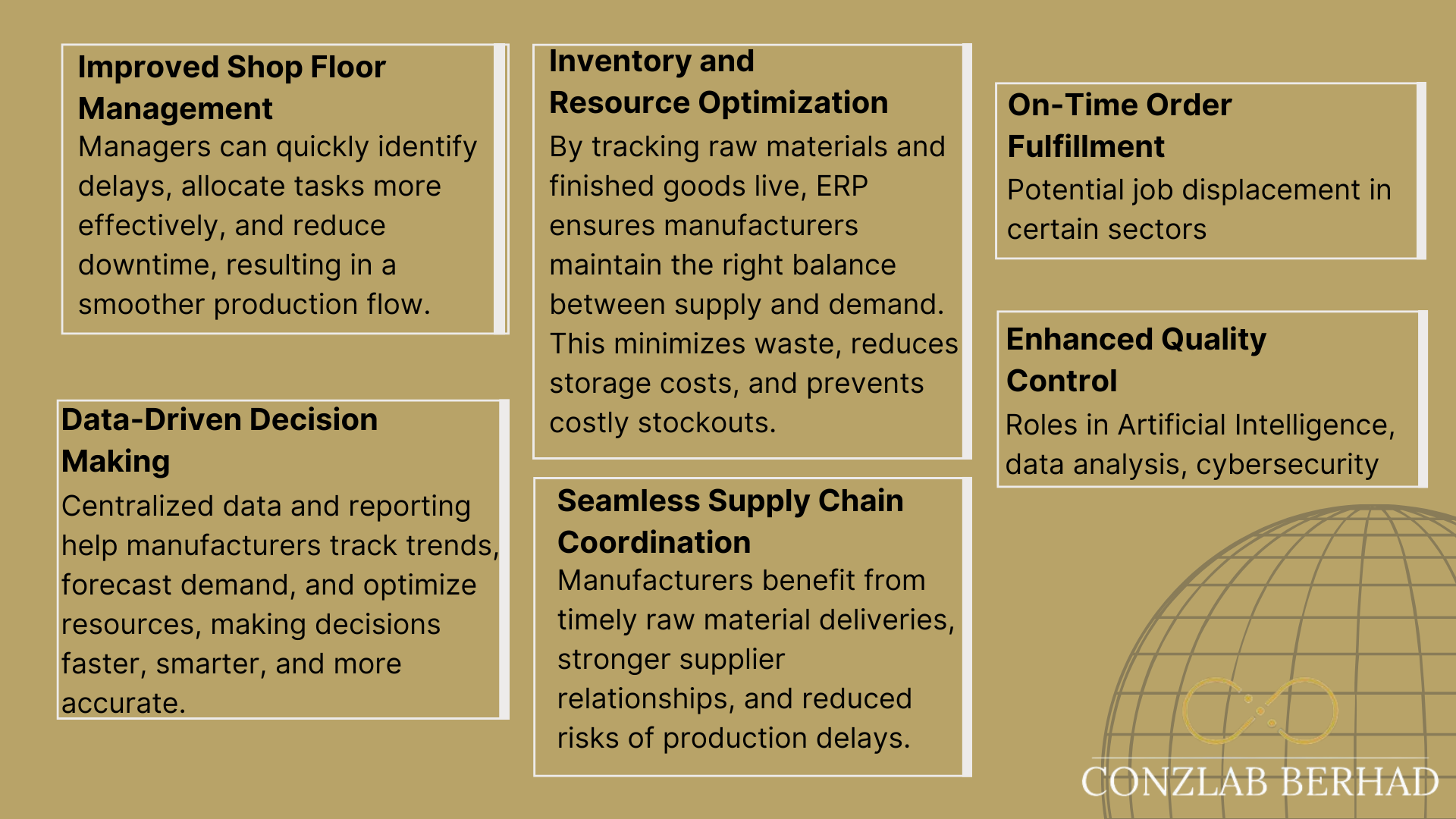

Key Benefits of ERP in Manufacturing

Implementing ERP in manufacturing is more than just making daily operations easier. It lays the groundwork for long-term efficiency and growth. By connecting every stage of production, ERP helps manufacturers use resources wisely, speed up processes, and maintain consistent quality. The advantages go beyond saving costs, leading to stronger customer trust, smarter decision-making, and a competitive edge in the market.

Reduced Waste

- ERP tracks raw materials and resources in real time, helping businesses avoid overstocking or shortages.

- This reduces material wastage and lowers production costs.

Faster Production Cycles

- Automated scheduling and workflow management minimize delays on the shop floor.

- ERP ensures every process, from order entry to final delivery, moves faster and more efficiently.

Improved Product Quality

- Quality control modules in ERP detect issues early in the production process.

- This leads to fewer defective products and higher customer satisfaction.

Stronger Customer Satisfaction

- Real-time order tracking allows businesses to provide customers with accurate delivery updates.

- On-time delivery and consistent product quality build long-term trust and loyalty.

Better Decision-Making

- ERP consolidates all manufacturing data into a single dashboard.

- Managers can analyze production trends, identify bottlenecks, and make informed decisions quickly.

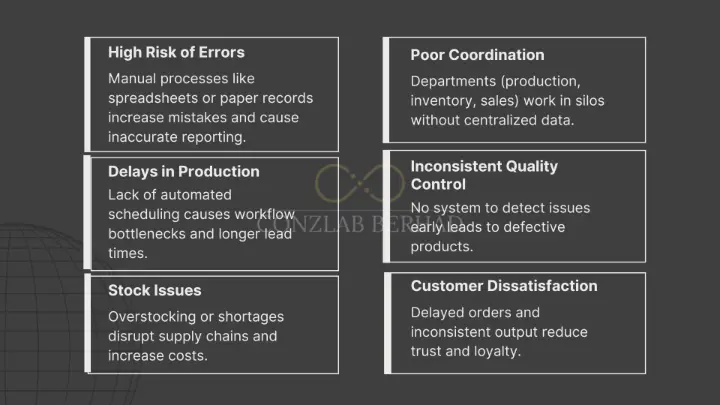

Challenges Without ERP

Manufacturers operating without ERP often struggle with inefficiencies that affect every part of their business. From manual data entry that leads to costly errors, to poor coordination between departments, these challenges make it hard to stay competitive. Production delays, stock mismanagement, and inconsistent quality control further add to the problems, creating higher costs and unhappy customers. Without a centralized system, businesses face greater risks, slower growth, and limited ability to meet today’s fast-changing market demands.

Conclusion

ERP is no longer just an IT system but a vital asset for modern manufacturing. By streamlining every step from raw material sourcing to customer delivery, ERP enables manufacturers to work more efficiently, cut costs, and remain competitive in a demanding market. Choosing to invest in ERP is more than simply improving processes. It is about preparing your manufacturing business for growth, resilience, and future innovation.

ERP is the bridge that connects the shop floor to customer satisfaction.

ERP tracks real-time production activities, machine performance, and labor allocation, allowing managers to address issues instantly and boost efficiency.

Yes, ERP monitors inventory and raw materials, helping businesses avoid overproduction, reduce storage costs, and minimize waste.

ERP connects suppliers, procurement, and logistics in one system, ensuring timely deliveries and preventing supply chain disruptions.

ERP in Manufacturing: Streamlining Operations from Shop Floor to Delivery